Resource Hub

How to implement a healthy driver fatigue policy with systems – and comply with legislation

Published February 24, 2022 in Blog

There is no denying that driver fatigue and the consequences of drowsy driving are serious.

Numerous studies have demonstrated that driving when fatigued can have the same dangerous outcomes as driving under the influence of alcohol or drugs, with both conditions being associated with reduced alertness and attentiveness, slower reaction times, and impaired decision-making abilities¹, ².

In light of this, eliminating or minimising driver fatigue and its related risks is a high priority for many bus companies.

The issue itself is at the heart of the problem. However, if bus operators lack a readily accessible driver fatigue policy for staff members and an easy-to-implement process or system for monitoring and flagging policy breaches, they risk being held legally liable for consequences that result from allowing operations to continue under dangerous conditions.

While the driver is expected to comply with policies, the bus operator also has a duty of care to produce a safe work roster that gives employees adequate time to sleep, recover, and perform their social and domestic responsibilities³.

Governments and industry bodies recognise that bus operators have a responsibility to systematically manage their fatigue risk to effectively monitor their drivers, with enforcement, compliance, regulations, standards, and reviews undertaken by authorities to ensure safe operations¹.

Tight schedules and inadequate auditing can cause fatigue legislation breaches, with drivers exceeding maximum allowable work time. Realistic timetables with rest stops included are needed so drivers can safely perform their duties and combat fatigue.

Tragically, fatalities involving heavy vehicles still occur. Fatigue management is being scrutinised and is undergoing implemented change1. Drivers who feel pressured to drive while fatigued should call the NHVR’s Heavy Vehicle Confidential Reporting Line on 1800 931 785.

What is the existing situation for driver fatigue monitoring?

Historically, Australian and New Zealand authorities have focused mainly on the trucking industry when it comes to driver fatigue monitoring. However, with trucking having been under the microscope for some time, industry regulators have turned their attention to bus operators. As per the Heavy Vehicle (Fatigue Management) National Regulation, these are the standard work and rest hourly requirements for solo drivers operating a bus or a coach:

* Stationary rest time is the time a driver spends out of a heavy vehicle or in an approved sleeper berth of a stationary heavy vehicle.

# Night rest breaks are seven continuous hours stationary rest time taken between the hours of 10 pm on a day and 8 am on the next day (using the time zone of the base of the driver) or a 24 continuous hours stationary rest break.

There have been cases where bus operators have been fined for breaching NHVR guidelines. Bus drivers have also threatened industrial action if standards are not improved, such as longer breaks between shifts and reduced hours.

How does your bus company measure against these requirements?

It is not uncommon in the transportation industry, where there is ongoing pressure to perform to tight schedules, for people to work within a culture of ‘powering through’³. Are your operations ensuring that there is adequate policing and auditing of fatigue management regulations?

While the laws and regulations around heavy vehicle driver fatigue are often complex and difficult to comply with4, it doesn’t have to be onerous for your bus company. By having a policy in place and using an integrated system to help automate the monitoring and regulation of driver shifts, you can place more focus on managing the causes of driver fatigue, which are often overlooked4. This makes the process of being able to manage compliance and act accordingly easier. It also eliminates pressure on management to manually keep track of staff compliance with fatigue policies.

Empirical evidence suggests that drivers perceive management support plays a major role in them taking positive actions towards preventing driver fatigue5. This is further supported by the observation of decreased reported fatigue in depots where positive management relationships are in place.

How does an Enterprise Resource Planning (ERP) system help fatigue management?

An ERP system provides a bus operator with a ‘single source of truth’. It is a central data repository that enhances incident analysis capabilities, as there is potential to draw correlations between staff behaviour and incidents.

‘An Enterprise Resource Planning (ERP) system that is tailor-made for bus operations will have the ability to monitor rosters, driver sign-on and off time and trigger alerts when proposed shift allocations go against guidelines.

Enterprise Resource Planning (ERP) system explanation for bus

Enterprise Resource Planning (ERP) system explanation for bus

An example of this could be discovering a trend that late driver check-ins coincide with fatigue-related occurrences. Such information could dramatically change your company’s ability to take pre-emptive action and instil new practices or policies to avoid risky situations. A bus-specific ERP system allows you to not only meet the requirement of adhering to driver fatigue legislation, but also ensures your company is following industry best practices.

ERP tools help manage driver fatigue

Your company also has the added benefit of being able to build trust with authorities through a well-implemented policy and the ability to produce documented verification of your compliance with standards and legislation using robust, evidence-based data.

The benefits of implementing a technology-driven fatigue management system include:

- Automated fatigue checks – alerts are provided if a rule will be breached, and automatically updates the roster in real time when changes are made.

- Entire workforce fatigue management – systems give a complete overview which ensures the entire workforce stays within set fatigue management parameters across the entire roster, and on the day of operations, and

- Effective rostering – where only drivers who are below fatigue thresholds are rostered for upcoming shifts – keeping drivers fresh.

Technology enables a modern approach to fatigue management that provides visibility and better fatigue risk management. This helps balance shifts based on when and how long drivers work for, and how many times over the past few weeks.

New Trapeze Bus ERP Enhancement – Advanced Fatigue Management Rules Engine

Trapeze has updated our bus ERP solution, TIMS, with the Advanced Fatigue Management Rules Engine. It provides enhanced fatigue management features and helps bus operators manage fatigue across their entire workforce on the day of operations. It considers the planned shift cycle and takes into account the hours a bus driver has already worked and their upcoming shifts. It then compares this to fatigue guidelines and legislation and provides a warning of a compliance breach when allocating a driver to work.

Features include:

Despatch Integration

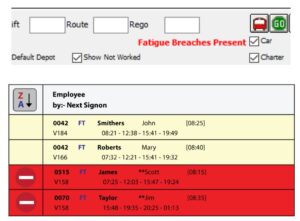

The Advanced Fatigue Module Rules Engine integrates with the Despatch Tool within the TIMS Operations Module. Providing Advanced Fatigue Management checking in the Day of Operations Despatch screen is essential to allow operators to make informed driver allocation decisions in real time. The Despatch screen is where the bulk of the day-to-day operational decisions are made, usually in a time-sensitive manner. Advanced Fatigue Management checking is performed live as changes are made to drivers work allocations in the Despatch screen.

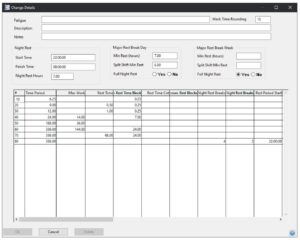

Fatigue Rulesets

The Advanced Fatigue Management Rules Engine is triggered to apply the defined Fatigue Ruleset by adding, removing or altering driver shift information. Breaches are visually displayed with the relevant information so informed decisions can be made and corrective action can be taken.

This allows bus operators to pragmatically implement fatigue policies, set manageable schedules, and carry out robust quality assurance measures to meet safety and regulatory obligations.

Fatigue Checking

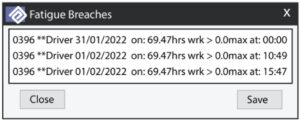

On the day of operations, fatigue checking occurs to ensure correct decisions are made. Shifts can be moved with the Roster tool, with fatigue management rules applied to the entire roster and breaches visually displayed. TIMS checks any roster change immediately and provides warnings and recommendations if a breach occurs. TIMS also informs the operator about what rule is breached, what caused it, and what time it will occur.

Fatigue breach on ERP software for public transport

Fatigue checking uses actual shift data and planned shift information. For example, a ‘soft breach’ means that a future breach will occur if a driver works a current shift and then works a planned future shift. Breaches are recorded and can be used for audits and training. Reporting functions are included so that fatigue breaches can be reviewed and reported on.

While roster staff control who is available to work on what day, operations staff determine which driver and bus are allocated to specific work on the day. During this time, if a fatigue breach alert is triggered, staff can re-think work allocations by choosing a different bus driver, or breaking the existing shift into smaller pieces so the original driver can be allocated a partial shift without causing a breach. In the case of a soft breach, the proceeding day/s rosters can be updated to avoid a hard breach during upcoming shifts.

Flexible Rules and Advanced Fatigue Management

Fatigue rules have multiple configuration options available to account for legislative requirements, but also have the flexibility to incorporate other requirements if required, such as custom rules. A ‘Fatigue Ruleset’ can have an unlimited number of rules associated with it. Hard fatigue requirements cannot be overwritten or modified.

The Advanced Fatigue Management Rules Engine supports the NHVR Advanced Fatigue Management (AFM) initiative by allowing custom fatigue rules to be applied, providing operational flexibility. This can help support an application for AFM accreditation from the NHVR and other regulatory bodies.

According to a 2021 NHVR survey6, operators who use AFM systems experience fewer fatigue-related incidents, a much-improved safety culture, and higher productivity.

Conclusion

Fatigue management is an important part of bus operations that requires careful management. Technology makes this process easier, faster, and informs decision making to ensure bus drivers don’t drive tired. The end result is enhanced safety for both drivers and passengers.

For more information about Trapeze’s fatigue management solutions for bus operators, please contact us.

(1) Department of Transport and Main Roads. (2020). Delivering heavy vehicle safety solutions together: Queensland’s Heavy Vehicle Safety Action Plan 2020–21.

(2) Watson, N. F., Morgenthaler, T., Chervin, R., Carden, K., Kirsch, D., … Wise, M. (2015). Confronting drowsy driving: The American academy of sleep medicine perspective. Journal of Clinical Sleep Medicine, 11(11), 1335–1336.

(3) Australian Transport Safety Bureau. (2017). Fatigue.

(4) National Transport Commission Australia. (2016). Heavy vehicle driver fatigue data: Final report May 2016.

(5) Biggs, H. C., Dingsdag, D. P., & Stenson, N. (2009) Fatigue factors affecting metropolitan bus drivers: A qualitative investigation. Work: A Journal of Prevention, Assessment, and Rehabilitation, 32(1). pp. 5-10.

(6) National Heavy Vehicle Regulator. (2021). AFM. An introduction to Advanced Fatigue Management.

Mode of Transport

Bus, Trams/Light Rail, Ferry

Solutions

Intelligent Transport Systems

Meet the author

Trapeze Group